We are Consistently Embraced Innovation to Provide a Superior Level of Excellence.

Factory Tour

Manufacturing Process

Plasma Cutting

Our computer controlled plasma cutting equipment provides one of the most efficient and least costly cutting methods available.

Although it doesn’t provide the same concentricity, tolerance or smooth square edge as Machincut, our plasma cutters minimize the heat affected zone that is usually associated with a plasma cut edge, allowing for better tool life and higher speeds and feeds when you are doing additional machining in-house.

High Definition Plasma Cutting System

Mcneil Steel & Alloys FZE High-Definition Plasma Cutting System with Plasma Beveling Precision High-Definition Cutting Combined With State-of-the-Art Plasma Edge Beveling Unsurpassed Flexibility in Processed Stainless and Nickel Alloy Plate Parts

Once again, Mcneil Steel & Alloys FZE is on the forefront of the implementation of plate processing equipment for the production of Stainless Steel and Nickel Alloy Plate Parts.

We’ve added a state-of-the-art High-Definition Plasma Cutter capable of cutting high definition up to 2.0″ (50.8mm). The machine is also equipped with a Plasma Edge Beveler that can bevel parts through 3.0″ (76.mm). Our high-definition cutting

system combines Y-axis linear ways with pitch line rack and pinion drives to provide the industry’s smoothest cut edge and precise holes. Wider end trucks with a maximum guide roller spread further stabilize the X-axis motion for the ultimate cut edge performance.

The new bevel cutting head, combined with a sophisticated software package, provides the most precise plasma cut edges available in the market today. The system’s unique design keeps the critical components away from the cutting torch, minimizing the risk of damage to the torch by slag, heat, and unwanted contact.

The plasma beveler head is capable of accurate beveled parts on any angle from +52 degrees to -52 degrees. Torch height is automatically controlled to an accuracy of +/- .006″ (15mm), so part integrity is maintained throughout the cut. Corner loop size down to 0.394″ (10mm) can be achieved without requiring start/stop commands. The result is accurate parts with square corners and minimal scrap up to 3.0″ (76.2mm) thick.

| Thickness Range Conventional Plasma | 3/16″ to 6.0 (4.8mm to 152.4mm) |

| Thickness Range High Definition | 3/16″ to 2.0 (4.8mm to 50.8mm) |

| Thickness Range Bevel Cut | 3/16″ to 3.0 (4.8mm to 76.2mm) |

| Bevel Range | +/- 52 degrees |

Plasma Beveling

Plasma beveling enables us to cut your parts to size and bevel the edges in one step. This cuts your manufacturing costs by eliminating or reducing downstream processing.

Most shapes can be beveled, including rectangles, circles, and parts created in a CAD program. Beveling can be performed on plate up to 3.0″ (76.2mm) thick, plus or minus 52 degrees, knife edge or with a land.

Abrasive Waterjet Cutting

At Mcneil Steel & Alloys FZE, we are committed to providing our customers the most efficient and cost-effective methods of cutting Stainless Steel and Nickel Alloy Plate and plate products. In addition to our already diverse capabilities of plate processing, we are now offering multiple abrasive waterjet cutting systems to address your cutting needs. Our two WMC Series machines feature four cutting heads, integrated abrasive removal and recycling systems, WindowsT-based PC machine control and programing, and 60,000 psi pumps.

Mcneil Steel & Alloys FZE abrasive waterjet cutting system can provide near-net shapes and intricate parts cut to the accuracy levels and close tolerances our customers require. Secondary finishing can now be minimized if not totally eliminated. Unlike other cutting processes,Mcneil Instruments Inc abrasive waterjet cutting system assures you of receiving

consistent superior edge quality with no heat-effected zone. The lack of a heat-effected zone enables us to nest patterns more closely providing better material yields for you the customer.

Our four machines with seven cutting heads and custom-designed water tables allow us to cut sizes ranging from your smallest parts up to pattern sizes of 160″ (4064mm) x 240″ (6096mm) on our standard machines and 156″ (3962mm) x 288″ (7315mm) on our five-axis system. We can cut pieces up to 6.0″ (152.4mm) thick and weighing up to 20,000 pounds.

5-Axis Abrasive Waterjet Cutting

Mcneil Steel & Alloys FZE’s latest addition to our state-of-the-art plate processing capabilities is our new Jet Edge EDGE X-5 five-axis abrasive waterjet cutting system.

It is capable of processing your most challenging three dimensional cutting requirements. This machine enables us to offer you cost-effective contour bevel parts, chamfer holes, and weld bevels including K-Bevels.

Machincut Rings & Discs

Our “speciality of the house.” Machined finishes are available at virtually the same cost as plasma cutting. Our rings and discs are machined to a tolerance of +1/16″ – .000″ on the O.D. and +.000″ – 1/16″ on the I.D. to give you a smoother edge with better concentricity than a plasma cut edge. In addition, you have no heat affected zone, which increases your tool life. We can turn up to 124″ (3150mm) OD, and face the surface of one or both sides to any special thickness or RMS finish. All of this means a lower ultimate “cost in use” to you.

With our unparalleled in-house processing capabilities, nearly any machined configuration is readily available. We can provide bevels, grooves or fine surface and edge finishes that you need.

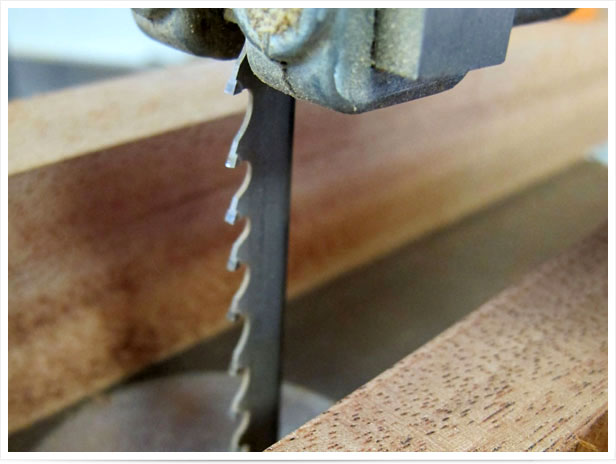

Bandsaw Cutting

Bandsaw cutting provides a better edge quality than plasma cutting, with no heat-affected zone on the edges. Ideal for rectangular plate and bars cut from plate from .250″ (6.3mm) thick to 6.0″ (152.4mm) thick; up to a maximum cut plate size of 124″ (3149.6mm) wide by 274″ (6959.6mm) long. Tolerances of +.125″ to -0″ on the width and length of the part can be achieved.

The Center was designed to process our largest full-size plates. As a result, we can provide a cut piece as large as 124″ wide and 274″ long..

Additionally, the saws can cut narrow bars. This is especially useful for supplying bars cut from plate for non-standard bar sizes and types.

Mcneil Steel & Alloys FZE offers bandsaw cutting, abrasive water jet cutting, plasma cutting, and extensive machining capabilities up to 124″ (3150 mm) OD under one roof. When matched with our outstanding service and our 18 million pound inventory of Stainless Steel and Nickel Alloy Plate, Mcneil Instruments Inc’s Bandsaw Cutting Center provides the complete package for a cutting service operation!

Drilling (Tubesheet & Baffle), Tapping, Counterboring

Our proprietary research and development in drilling technology, combined with our state-of-the-art automatic indexing drilling equipment, result in a very low cost per drilled hole.

Standard bolt-hole patterns can be drilled and shipped in the same turnaround time as machined ring or disc blanks. We also can provide thread tapping and additional counterboring when required.

Milling

Need a special edge finished with close tolerances on rectangular plate? Mcneil Steel & Alloys FZE can do this on our special heavy-duty milling machines.

Need the same edge finishes on shapes and configurations? Mcneil Steel & Alloys FZE can do contour milling on our sophisticated three axis, double column, vertical machining center. Edge beveling is also available.

Polishing

At Mcneil Steel & Alloys FZE, we’re highly experienced in polishing stainless and nickel alloy plate and can provide a standard #4 finish or a 5 RMS maximum when requested. This can be done on all shapes.

Flattening

Commercial mill flatness tolerances for stainless steel plate and nickel alloy plate don’t meet the requirements of most customers today. At Mcneil Instruments Inc, we do much better. Nearly every plate product we ship is individually flattened prior to shipping –at no additional cost to you. When your flatness requirement is especially critical, we have capabilities of flattening stainless steel plate to within .0625″ (1.6mm), based on the thickness and size of the piece. Flattening tube sheet blanks is Mcneil Steel & Alloys FZE’s specialty.

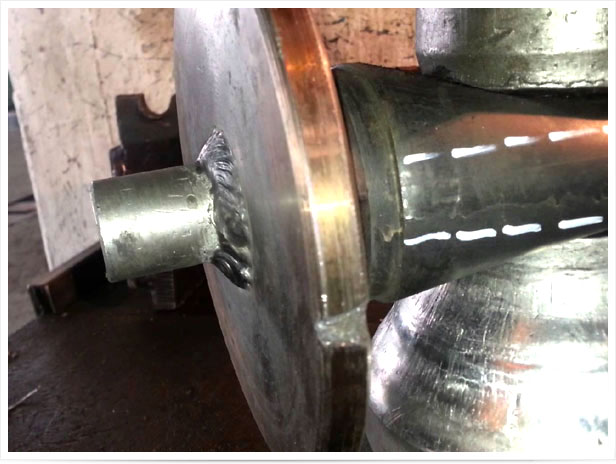

Rolled & Welded Rings

Mcneil Steel & Alloys FZE’s rolling and welding processes economically give you the large diameter rings you need by eliminating the yield loss of standard plate rings.

We can cut stainless and nickel alloy bars and roll them into easy-way or hard-way rings, within full ASME compliance, including code welding and x-ray.

Research & Development

Our innovation and process-focused team constantly challenges our existing product portfolio. The team and develops new products and upgrades existing products to benefit our customers. We use the concept of “Design for Six Sigma” as a platform for Product development and follow a well laid out procedure for all our developments. Our expert Techno-commercial team always keeps the end user in mind and works closely with customer for their customised product offerings.

Analytical Formulations

Using the basic laws of physics and hydraulics, we use analytical formulas, wherever applicable, for a basic design formulation. This helps us design the product from First Principles. Our team refers to the latest published papers and standards during the process.

3D & 2D Modelling

After these calculations, we create options through Solid Models via 2D and 3D design packages which:

- Resolve physical conflicts and fine-tunes the product

- Help us drive the cost savings opportunities

- Enable new developments to be finalised with speed and detailing

The models are then validated by our manufacturing experts.

Finite Element Modelling & Analysis

- The developed design is validated virtually using the latest design and analysis methodology – Finite Element Analysis (FEA).

- Through FEA, the solid model is first meshed, applied with a suitable material model and subjected to appropriate boundary conditions and solved using Solid-WORKS & ANSYS

- Graphical output helps compare the Stresses/Strains with material parameters.

- This virtual validation is iterated until a product is designed and validated that can be manufactured.

Manufacturing

- Based on the virtual validation, manufacturing drawings are prepared.

- Samples are made on our in-house CNC machines to the highest quality standards.

Final Testing

- With our belief that “seeing is believing”, the manufactured product is then taken to our centralised state-of-the-art laboratory

- A range of performance tests are conducted to validate performance parameters

The newly designed product is then offered to our clients