Material of Construction

Stainless Steel: ASTM A182 F304 / 304L / 304H / 316 / 316L / 317 / 317L / 321 / 310 / 347 / 904L etc.

Carbon Steel: ASTM A105 / A694F42 / 46 / 52 / 56 / 60 / 65 / 70 / A350 LF3 / A350 LF2 etc.

Alloy Steel: ASTM A182 Fl / F5 / F9 / F11 / F22 / F91 etc.

Others: Monel, Nickel, Inconel, Hastalloy, Duplex and Super Duplex Steel, Titanium, Copper, Brass, Bronze, Tantalum, Bismuth, Aluminium, High-Speed Steel, Zinc, Lead, etc.

Features

- Anti oxidization

- Excellent performance

- Resilient

- Superior tensile strength

- Reliable

- Excellent quality

Styles Available

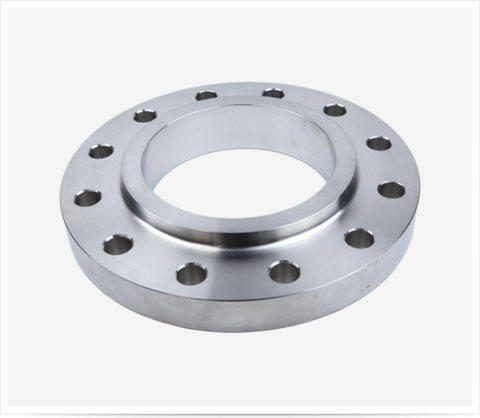

- Flat face

- Raised face

- Resilient

- Tongue

- Groove or ring joint

Trusted Vendor for Custom Industrial Solutions

McNeil also acts as a skilled vendor, offering tailored flange solutions to meet specific project requirements. With superior tensile strength, durability, and anti-oxidation resistance, our flanges support safe and reliable operation in every industrial setup.

Stainless Steel Flanges Manufacturing Standards

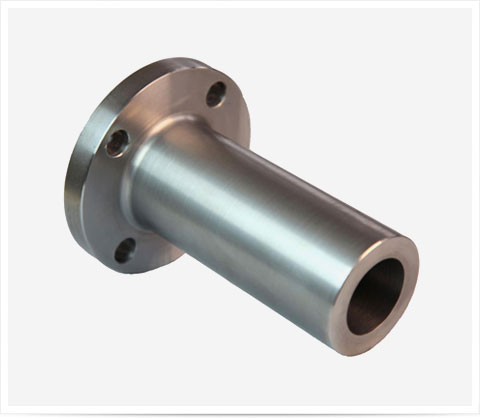

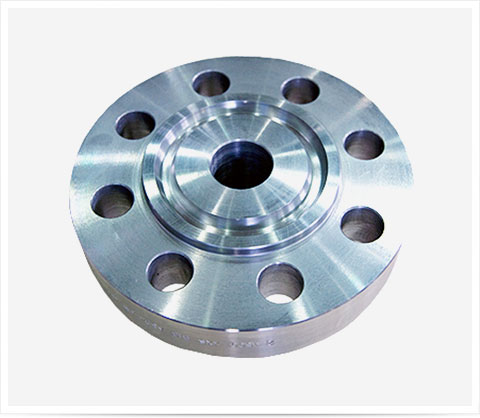

ASME/ANSI B16.5: WELDING NECK FLANGE, SLIP-ON FLANGE, BLIND FLANGE,HIGH HUB BLIND FLANGE, SOCKET WELD FLANGE, LAPJOINT FLANGE, THREADED FLANGE, RING TYPE JOINT FLANGE.

Pressure Class – 150, 300, 400 , 600 , 900, 1500 , 2500

ASME/ANSI B16.36: (ORIFICE FLANGES) WELDING NECK FLANGE, SLIPON FLANGE, THREADED FLANGE.

Pressure Class – 300, 400 , 600 , 900, 1500 , 2500

ASTM/ANSI B16.48: Pressure Class – 150, 300, 400 , 600 , 900,1500, 2500

MSS SP44: WELDING NECK FLANGE, BLIND FLANGE.

Pressure Class – 300, 400 , 600 , 900

API 6A: WELDING NECK FLANGE, THREAD FLANGE,BLIND FLANGE.

Pressure – 2000Psi, 3000Psi, 5000Psi, 10000Psi, 15000Psi, 20000Psi, 25000Psi

Trusted Vendor for Custom Solutions

McNeil also serves as a skilled vendor, offering customized flange solutions to meet specific project requirements. With superior tensile strength, anti-oxidation protection, and resilient performance, our flanges deliver dependable operation across all industrial applications.

Where Flange Decisions Make the Biggest Difference

At Mcneil Alloys, we’ve learned that the most important flange decisions are usually made long before installation begins. I often see problems traced back to small assumptions choosing a flange that looks correct on paper but doesn’t fully match how the system will operate day to day.

We pay close attention to the points where systems are under the most stress: connection joints that experience pressure variation, temperature changes, or limited access for maintenance. These are the places where flange selection truly matters. Our team looks beyond size and rating to consider alignment tolerance, facing condition, and how the joint will behave over time, not just at startup.

When the right flange is chosen early, everything downstream becomes easier installation goes smoother, sealing is more reliable, and long-term operation is less demanding. That’s where we believe real value is created.

Conclusion

We believe flange supply is about more than meeting specifications it’s about supporting systems that need to perform reliably over time. When the right decisions are made early and the right attention is given to detail, flanges do their job quietly and effectively. That’s what we aim for in every project: supplying flanges you don’t have to think about once they’re installed.

Mcneil Alloys delivers high-performance flanges designed to strengthen your pipeline integrity, improve operational safety, and ensure long-lasting service life. For quotations, technical assistance, or project supplies Contact Mcneil Alloys today and experience precision you can trust.