When you’re dealing with Chrome Moly pipes, the grade alone is never the full story. What really matters is how the pipe will behave once it’s installed and operating under heat and pressure. We look at Chrome Moly grades from a practical point of view where they’re being used, how long they’re expected to run, and what kind of operating conditions they’ll face on site.

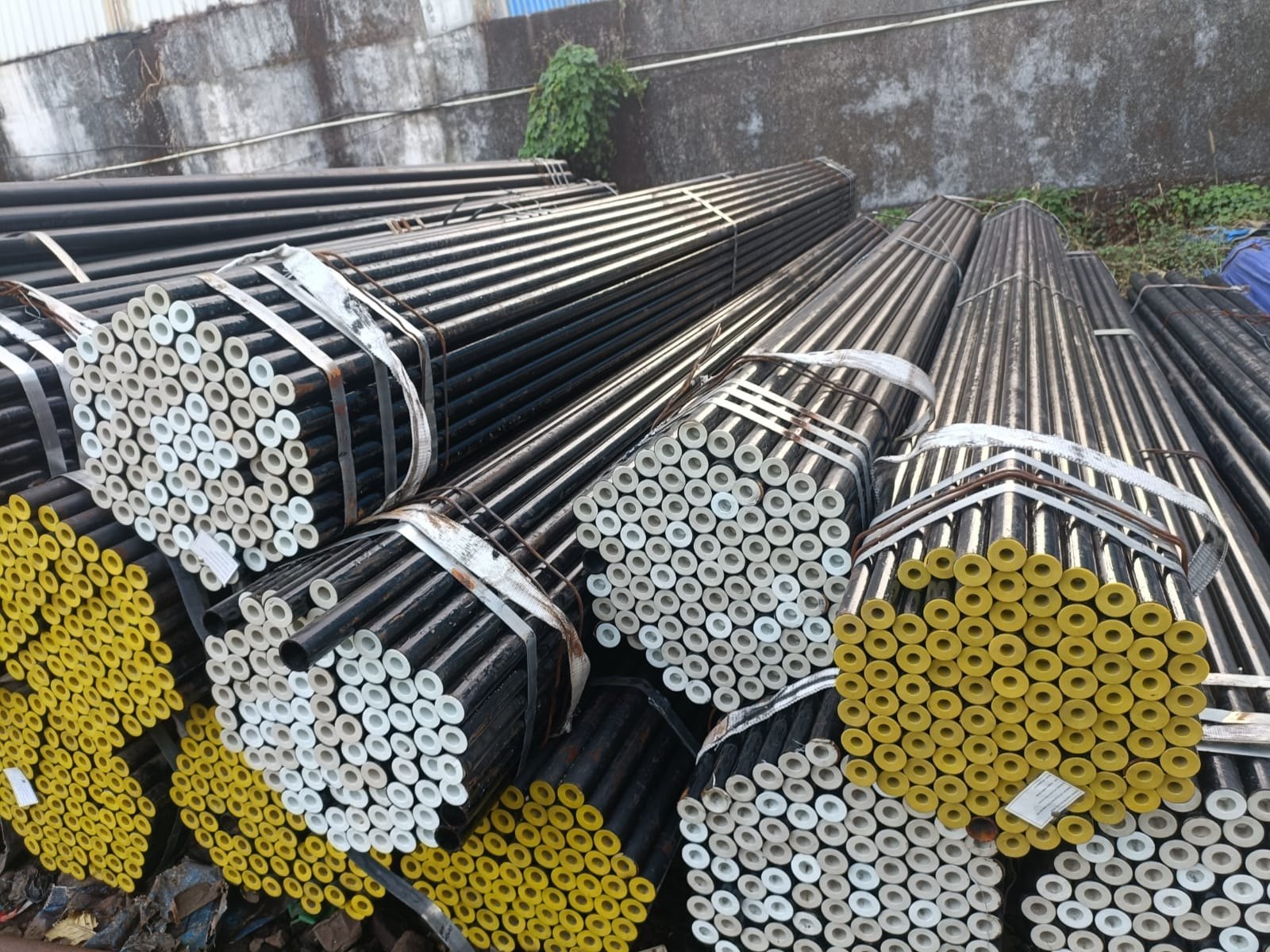

We supply Chrome Moly Pipes in P5, P9, P11, P22, and P91 grades for power plants, refineries, steam systems, and high-temperature industrial piping. Some customers approach us with detailed specifications, while others are still comparing grades. In both situations, we work closely with you to make sure the selected material actually suits your application, not just the drawing.

If you’re sourcing Chrome Moly Pipes in the UAE for a new project or replacement work, we’re here to help you select the right grade and move forward with confidence. Share your operating conditions with us, and we’ll take it from there.

With coordinated supply capabilities from the UAE, we support both local project timelines and export requirements, delivering alloy steel pipes that integrate seamlessly into demanding operating systems and long-term industrial installations.